Fabric

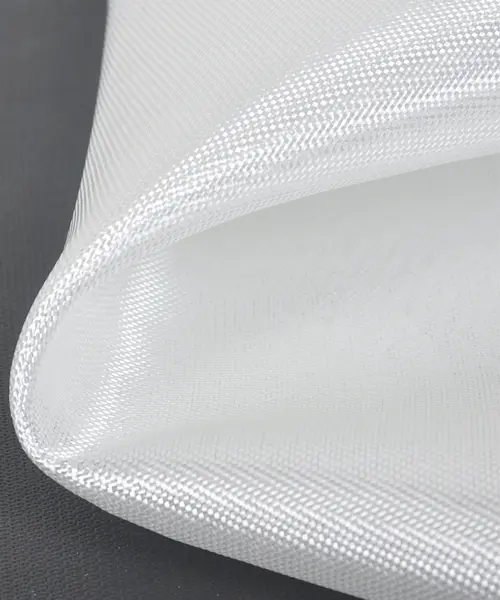

We provide fiberglass cloth, high silica fiber cloth, aramid fiber cloth, basalt fiber cloth, and processing for these fiber cloths, such as coated silicone cloth, Teflon cloth, PU cloth, fire blanket cloth, etc. There are many corresponding product categories, with a very wide range of applications.

Our engineers are online to provide material solutions. If you are unsure which fiber cloth materials are suitable for you, please contact our engineers. The vast majority of materials can provide free sample services.

Some Products of Fabric

Our Factory Offers a 1 Square Meter Sample for Free.

FAQ

Here are some common questions and answers. You can also contact us directly for assistance.

OEM & ODM, Not Retailer

Contact us for material application solutions.

Products Recommended

We have a range of products that we think might catch your eye: